Assembling the mash tun was really quite simple (and quick) once I had all the correct parts. I had to make a second trip, this time to A-boy, to get a smaller close nipple and braided line. The images will link to larger versions when clicked. Well, without further ado.

Step One: Get a cooler

I’m using a rubbermaid 10 gallon drink cooler from Home Depot (notice the logo), though this can be done with a smaller or rectangular cooler as well

Step Two: Remove the faucet

I did this in the store to make sure I had the right diameter of close nipple. Use a crescent wrench to hold the nut on the inside in place and twist on the outside faucet.

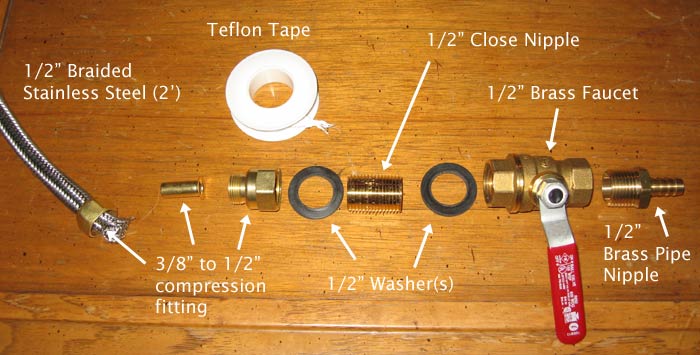

Assemble new manifold and drain system

Here’s how the pieces are assembled, though only put one half on, because you have to put the close nipple through the hole in the cooler before tightening up. Use teflon tape on each threaded fitting. I installed the internal compression fitting and washer first, inserted it through the cooler, then installed the exterior washer and faucet. Don’t over-tighten the assembly or you’ll damage the washers. I tightened just a little bit more than was possible by hand.

Moment of truth, part 1

If everything seems to fight right, give it a dry run. Well, a wet run. Add hot water to the tun and let it sit for 20 minutes or so to see if the vessel remains water-tight. If so, you’re ready to brew. See, that was cake.

Moment of truth, part 2

To be continued…

Well done! Very nice diagram too. Let us know how it works. I could see using this if I go all grain. For now…I’ll just have to sock it away.

What a wonderful smell. The mash went really well, though I forgot to monitor volume to calculate my efficiency. Also, the pocket thermometer I bought is a piece of shit. Sure, you can adjust it, but when it moves in 10 degree increments, you tend to question it’s accuracy.

Excellent work on the photos. I just got that exact cooler on Ebay yesterday (it’s better when you win it), and I’m just going to print your picture out when I go to the plumbing supply store.

thanks

Nice job on the illustrations. I printed out the picture so I can give it to my customers. I’ll also let them know of this website so they can come and look at the full article. i was going to strip my tun down but just have been; (pick one) a. too busy working; b. too lazy; c. too busy brewing.

I found this site looking for ideas for Bravo hops.

Thanks for the parts breakdown.

Nice work, doing that myself today. Does the braided stainless steel have holes in it, and is it sealed at the end?

The terminus isn’t sealed, but I crushed it with my fingers to get it to close. It may be worth going with something like a zip tie to keep it crimped, but so far its worked fine. Good luck.